When embarking on a concrete project, one of the most crucial aspects to consider is reinforcement. Proper reinforcement can significantly enhance the strength and durability of your concrete structure. So, how much wire mesh do you need for concrete?

The general rule of thumb is to use 6×6 10/10 welded wire mesh for most residential concrete projects, covering the entire area to be poured. This typically means one sheet of wire mesh per 100 square feet of concrete.

However, this answer may not be sufficient for all situations. The amount of wire mesh needed can vary depending on several factors, including the specific type of project, local building codes, and the expected load on the concrete. Continue reading to learn about these variables and how they might affect your wire mesh requirements.

Factors That Affect Wire Mesh Requirements

The amount of wire mesh you need for your concrete project isn’t always a one-size-fits-all solution. Several factors can influence the quantity and type of wire mesh required:

1. Project Type: Different concrete applications have varying reinforcement needs. A driveway may require more robust reinforcement than a sidewalk due to the heavier loads it will bear.

2. Concrete Thickness: Thicker slabs generally need stronger reinforcement, which might mean using a heavier gauge wire mesh or multiple layers.

3. Soil Conditions: If you’re pouring concrete on unstable or poorly compacted soil, you might need additional reinforcement to prevent cracking and shifting.

4. Local Building Codes: Always check your local regulations, as they may specify minimum reinforcement requirements for different types of projects.

5. Load Expectations: If your concrete will be supporting heavy equipment or vehicles, you’ll likely need stronger reinforcement than for a simple patio.

What Are The Alternatives To Wire Mesh For Concrete Reinforcement?

While wire mesh is a popular choice for concrete reinforcement, it’s not the only option available. Understanding alternatives can help you make an informed decision for your project

:

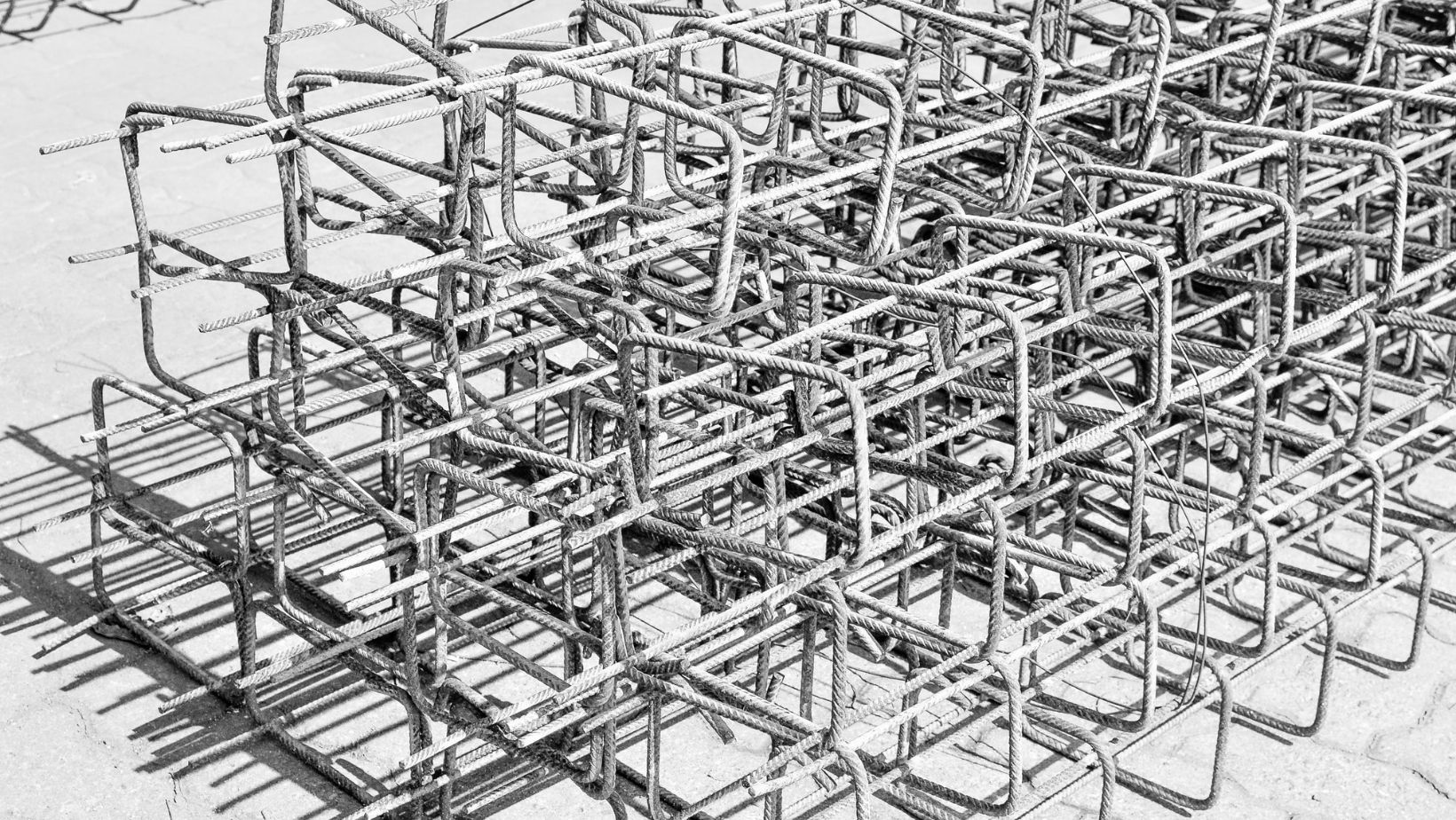

1. Rebar: Steel reinforcing bars, or rebar, provide excellent strength and are often used in conjunction with or instead of wire mesh for heavier-duty applications.

2. Fiber Reinforcement: Synthetic or steel fibers can be mixed directly into the concrete, providing uniform reinforcement throughout the slab.

3. Post-Tensioning: This method involves running high-strength steel cables through the concrete and tensioning them after the concrete has cured.

4. Expanded Metal Mesh: This alternative offers greater strength than standard wire mesh and is often used in industrial applications.

5. Bamboo Reinforcement: In some regions, bamboo is used as an eco-friendly alternative to steel reinforcement, although it’s not suitable for all applications.

How Do I Install Wire Mesh In Concrete Properly?

Proper installation of wire mesh is crucial to ensure it effectively reinforces your concrete. First, find a quality concrete supplies company. From there, here are some key points to remember:

1. Overlap: When using multiple sheets of wire mesh, overlap them by at least 6 inches to ensure continuous reinforcement.

2. Elevation: The wire mesh should be positioned in the middle of the concrete slab. Use wire mesh supports or “chairs” to elevate it to the correct height before pouring.

3. Cutting: Use wire cutters to trim the mesh to fit your project area. Remember to wear gloves and eye protection when cutting.

4. Securing: Tie overlapping sections together with wire ties to prevent shifting during the concrete pour.

5. Coverage: Ensure the wire mesh extends to within a few inches of the edges of your concrete area, but not so close that it’s visible after pouring.

By following these guidelines, you’ll maximize the effectiveness of your wire mesh reinforcement, contributing to a stronger, more durable concrete structure.

What Are The Pros And Cons Of Using Wire Mesh In Concrete?

Like any construction material, wire mesh has its advantages and disadvantages.

Understanding these can help you decide if it’s the right choice for your project:

Pros:

1. Cost-effective: Wire mesh is generally less expensive than other reinforcement options like rebar.

2. Easy to handle: It’s lightweight and can be cut to size easily, making it convenient for DIY projects.

3. Uniform reinforcement: Wire mesh provides consistent reinforcement across the entire concrete slab.

4. Crack control: It helps distribute stresses evenly, reducing the likelihood of large cracks forming.

Cons:

1. Limited strength: For heavy-duty applications, wire mesh may not provide sufficient reinforcement on its own.

2. Placement issues: If not properly elevated, it may sink to the bottom of the slab, reducing its effectiveness.

3. Potential for corrosion: In certain environments, wire mesh can rust if not properly protected.

4. Not suitable for all projects: Some complex concrete structures may require more robust reinforcement methods.

Consider these factors carefully when deciding whether wire mesh is the best reinforcement option for your specific concrete project.

How Does Wire Mesh Compare To Fiber Reinforcement For Concrete?

As fiber reinforcement becomes increasingly popular, many wonder how it stacks up against traditional wire mesh. Here’s a comparison of the two:

1. Installation: Wire mesh requires careful placement within the concrete, while fibers are simply mixed into the concrete, saving time and labor.

2. Uniform reinforcement: Fibers provide three-dimensional reinforcement throughout the entire concrete mix, while wire mesh reinforces only in a single plane.

3. Crack resistance: Both methods help control cracking, but fibers can be more effective at preventing microscopic cracks from forming.

4. Strength: Wire mesh typically provides better tensile strength, especially for larger slabs or higher-load applications.

5. Cost: The initial cost of fiber reinforcement is often higher, but labor savings during installation can offset this.

6. Versatility: Fiber reinforcement works well in complex shapes and thin sections where wire mesh might be difficult to place.

7. Durability: Wire mesh can potentially rust if exposed, while synthetic fibers don’t have this issue.

8. Building codes: Some local codes may still prefer or require wire mesh for certain applications, so always check local regulations.

Ultimately, the choice between wire mesh and fiber reinforcement depends on your specific project requirements, budget, and local building codes. In some cases, a combination of both methods might even be the best solution.

Moving Forward With Your Concrete Project

Now that you have a comprehensive understanding of wire mesh reinforcement for concrete, it’s time to take action. Before starting your project, consult with a local concrete professional or your area’s building department to ensure you’re using the appropriate reinforcement for your specific application. This step will help you avoid potential issues down the line and ensure your concrete structure is built to last.